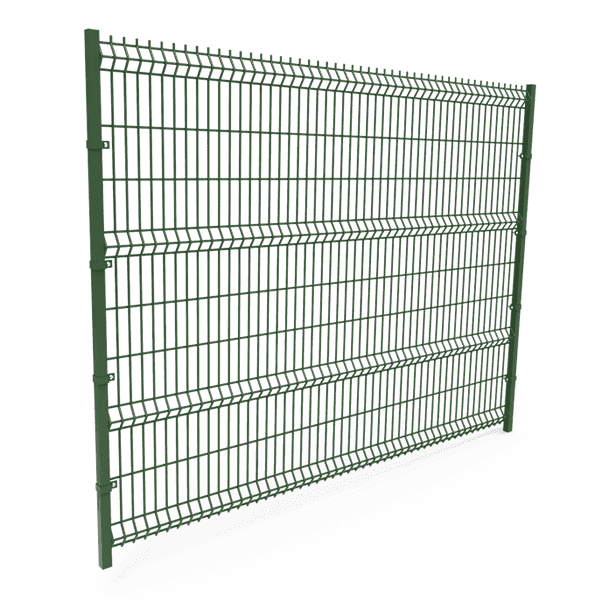

Curvy Welded Fence

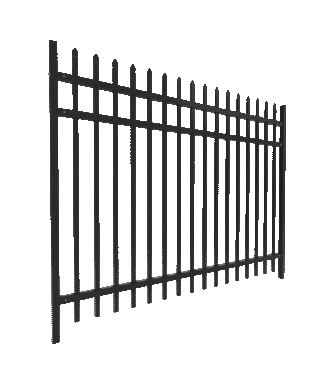

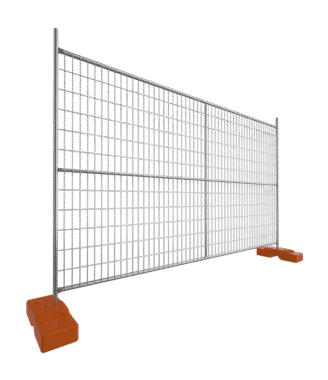

Double-Wire Mesh Fence is a mesh guardrail made from low-carbon steel wire or PVC-coated wire through a welding process, featuring a double-wire edge design that enhances overall stability. The main post specification is 1.8 meters in height paired with a 3-meter crossbeam. The surface is treated with dip plastic coating, galvanizing, or baking paint to improve corrosion resistance. This product is widely used in scenarios such as expressway closure mesh, railway isolation fencing, and residential community enclosures. It features a push-fit installation characteristic and is equipped with components like rain caps and connection clips for rapid assembly.

Structural Characteristics

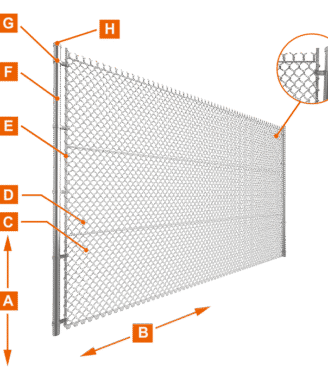

Utilizes low-carbon steel wire or PVC-coated wire as the main material for the posts.

Four horizontal reinforcing ribs are set to enhance structural strength [1].

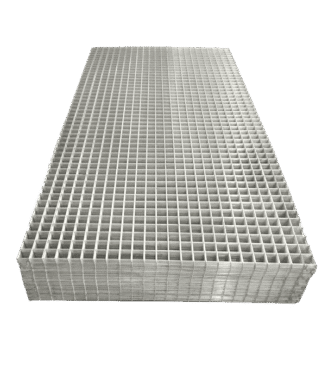

The mesh panel is formed by welding low-carbon steel wire or PVC-coated wire into diamond-shaped grids, with a standard aperture of 9cm × 17cm.

Product accessories include:

Anti-theft bolts (Specification: M8×35)

U-shaped connection clips (3mm thickness)

PE rain caps (60mm diameter)

Expansion bolts (Specification: Φ10×100)

Application Scenarios

Primarily applied in three types of protective fields:

Traffic Isolation: Expressway median barriers, railway line closure mesh, airport flight zone boundaries.

Area Protection: Residential community boundary fencing, sports venue isolation zones, river embankment protection.

Special Uses: Livestock enclosure on farms, industrial and storage area isolation, temporary fencing for construction sites.

Installation & Maintenance

Installation must follow three technical specifications:

Groundwork Requirements: Avoid underground pipelines within a 1.5-meter radius during foundation treatment.

Post Placement: Vertical deviation of posts should be controlled within ±3°, and the driving depth error should not exceed ±2cm.

Bridge Section Installation: Requires the configuration of a flanged base (Specification: Φ180×10mm).

Maintenance includes three core points:

Inspect the integrity of the dip plastic coating annually before the rainy season.

Tighten loose connecting components quarterly.

Regularly remove debris attached to the mesh surface to prevent corrosion.